Sectors

Definion is changing sectors across the metal manufacturing industry.

Medical Technology

The Definion technology is the ideal solution for manufacturing advanced medical devices.

Handling the most important metals used in medicine.

Titanium is the most popular metal used in medical devices, especially for internal use in the human body. Other metals and alloys used frequently are stainless steel, cobalt-chrome, and nitinol. All of these metals are hard to machine with traditional techniques but can be machined effectively with Definion, lowering production costs and opening up new design possibilities for medical devices.

A sterile process.

Definion is a non–contact process, free from harmful chemicals or blast media, thus enabling a fully controlled and sterile environment for medical manufacturing.

Difficult features including internal features

Many medical devices need internal features. Definion’s patented method can process both external and internal features in a localised fashion, including both blind and through part features. This is of relevance to the biomedical industry, for devices with internal chambers, channels or reservoirs such as heart pumps.

Process control and traceability.

Definion is a turn–key system, fully automated and ready to deploy with a fully digital process from design to inspected part. High levels of repeatability with integrated measurement and inspection are ideal for a medical device production environment.

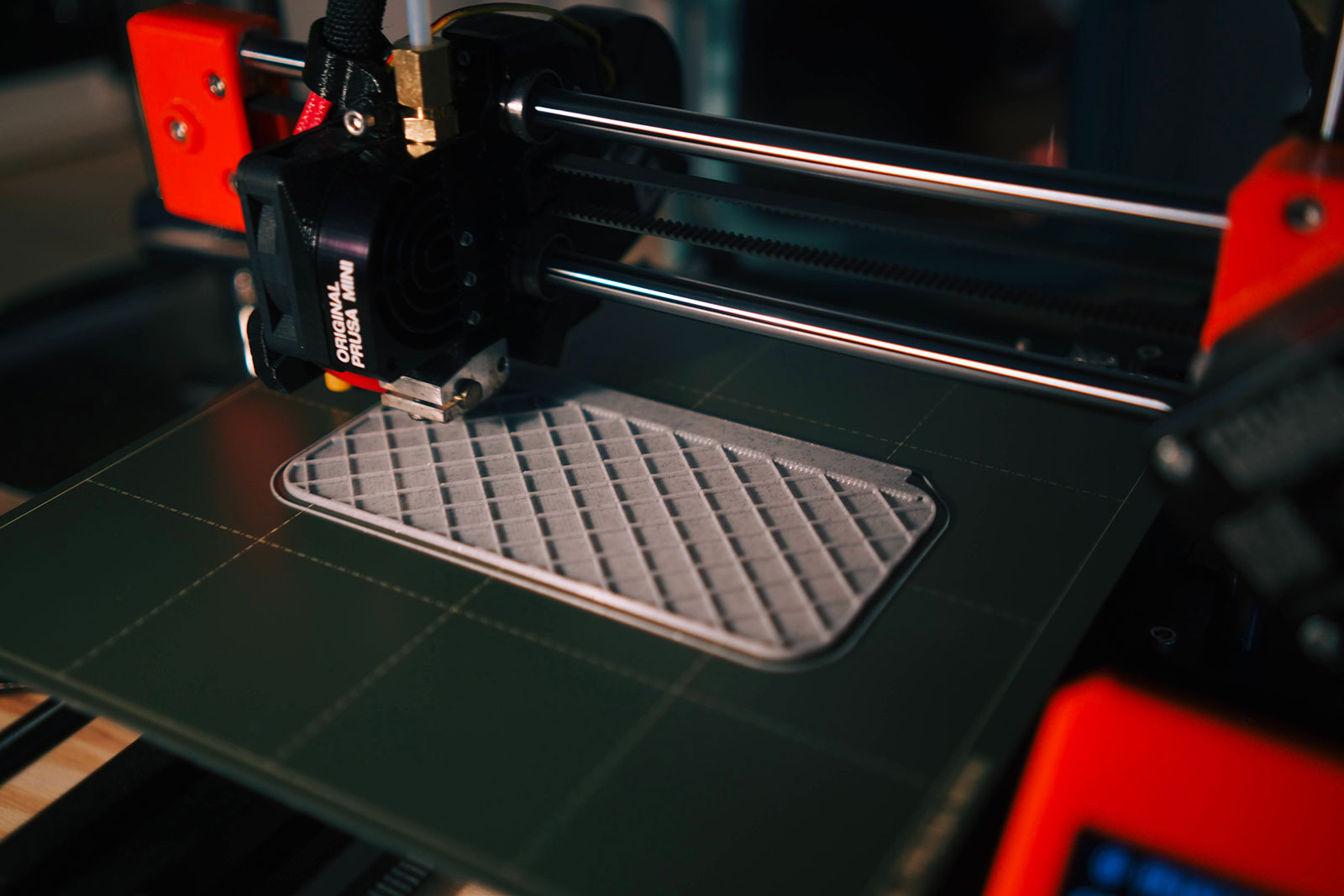

3D Printing

Definion provides the missing link in 3D printing.

The industrialization of 3D printing in metal has experienced immense progress, however, the printing processes on their own are not capable of generating surfaces or geometries to the specifications necessary for high end applications. Additional manufacturing steps are required, such as grinding, milling, polishing, and these steps are known as finishing, or post-processing.

The post-processing of 3D-printed parts in hard materials (Titanium, Cobalt Chrome, stainless steel) in particular is a multistep, asset intensive, consumable intensive and time-consuming aspect of manufacturing and and occupies significant floor footprint in a manufacturing facility. It is also unreliable as a number of the steps are carried out manually. It is estimated that post-processing of metal 3D printed parts contributes 50% of the cost of production.

Current methods for finishing 3D printed parts range from mechanical methods such as CNC machining, hand sanding, blasting, tumbling, and chemical surface treatments like descaling and pickling. Definion replaces these processes with a single, automated finishing step with superior results, reducing time, costs, errors, waste and reliance on skilled personnel. Definion integrates advanced measurement and inspection within the process.

Other methods can only produce one grade of finish over the entire part. Definion is selective, meaning that it can produce a range of finishes over the same part both externally, and, importantly, internally. Because current approaches are non – selective, a typical part may have to undergo several different steps in post-processing machines, increasing complexity, cost, time, and the risk of part failure and process interruption.

Definion is as much as 90% faster than alternative methods, particularly for metals such as titanium or cobalt chrome, whose hardness means that they take a long time to machine using traditional techniques.

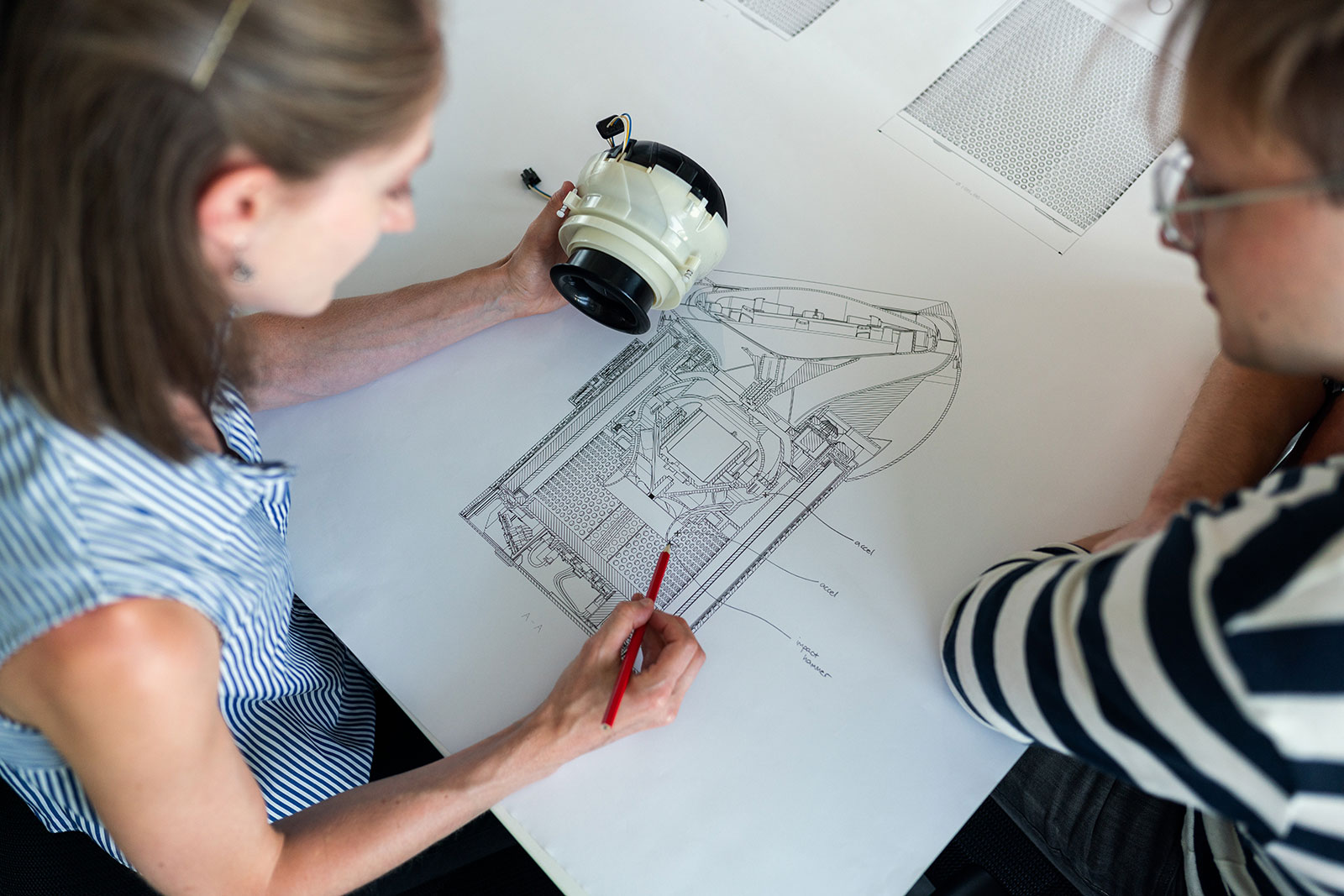

Aerospace & Automotive

Definion provides the solution to the exacting requirements for surface finishes needed in advanced automotive and aerospace applications.

Hard to machine metals

Definion is the ideal solution for the processing of emerging materials sets in aero engines, such as gamma titanium. This high performance material is known to be extremely difficult to process using conventional machining techniques.

Surface preparation

Preparing a surface for adhesive is a priority for automotive and aerospace applications. Adhesion is needed for metal to metal, metal to composites, etc for aerostructures such wings, fuselages, propellors etc. Definion can be used to roughen or prepare the surface for bonding and sealing. No masking is required prior to treating the surface.

Optimizing surface integrity

Optomising surface integrity in critical components. Conventional machining techniques can damage materials, particularly in stack drilling, where burrs from one layer can damage the layer below.