Applications

Transforming industrial processes in difficult materials used in advanced products.

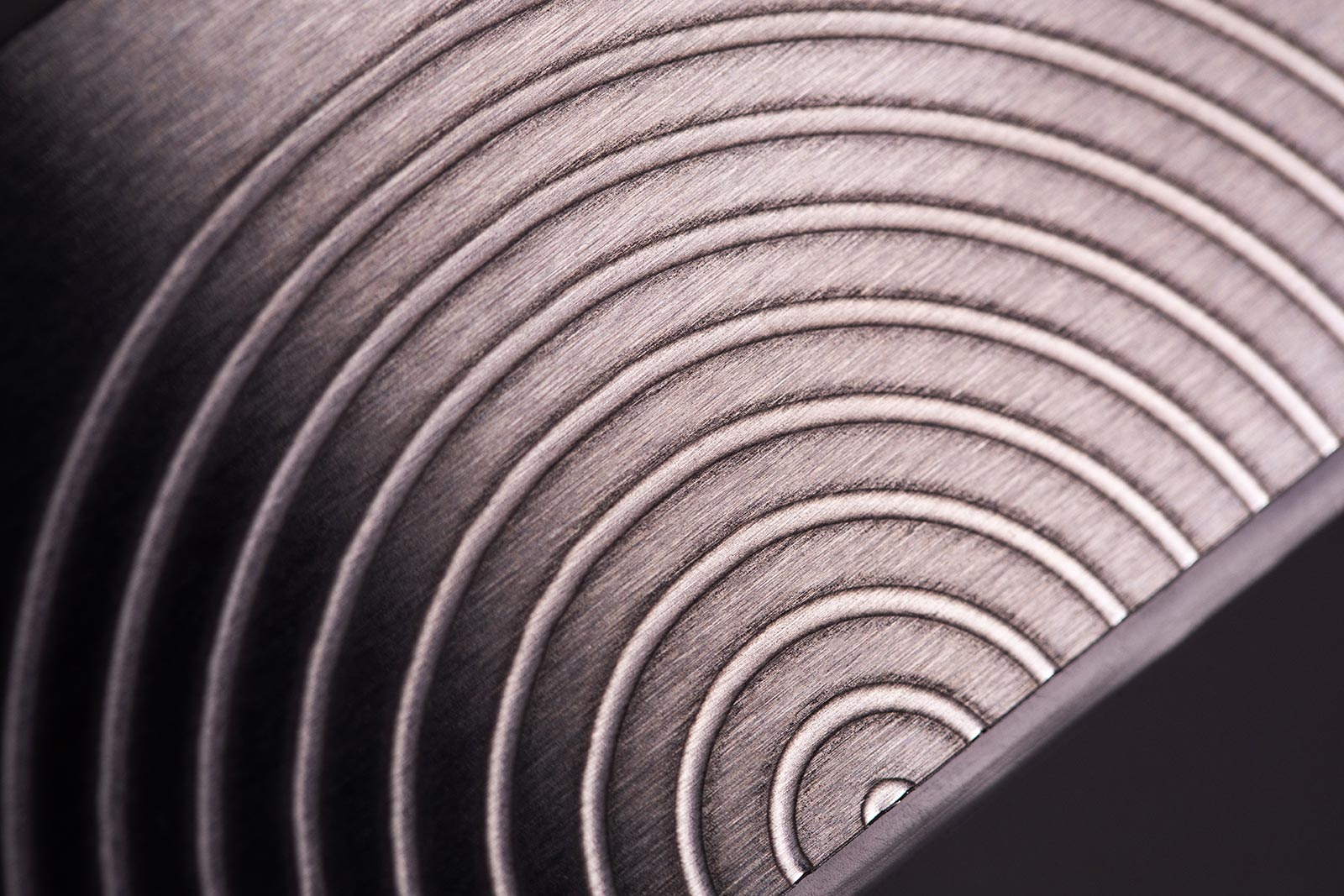

Finishing & Polishing

Definion brings a completely new dimension to finishing and polishing metal components.

A range of surface profiles can be achieved: from highly rough and textured, to mirror and super mirror finishes, down to an Ra of 60nm.

Most finishing technologies can only apply one finish at a time. With a highly directed micro jet, Definion can produce a range of finishes across a single part. This tailored finish is produced without tool changing, within a single, non-contact process step.

The finishing process is environmentally friendly and does not use dangerous chemicals or blast media.

Cutting

Cutting hard thin materials, such as cobalt chromium is challenging for the most sophisticated technologies.

Existing cutting processes can damage or bend the material, and will leave substantial burrs that need to be removed in post-processing. It is hard to achieve a clean, well-defined edge without heat effects or micro cracks.

The Definion process is particular suitable for cutting thin gauge material up to .5mm in thickness. No heat input means edges without sub surface stress or micro–cracking.

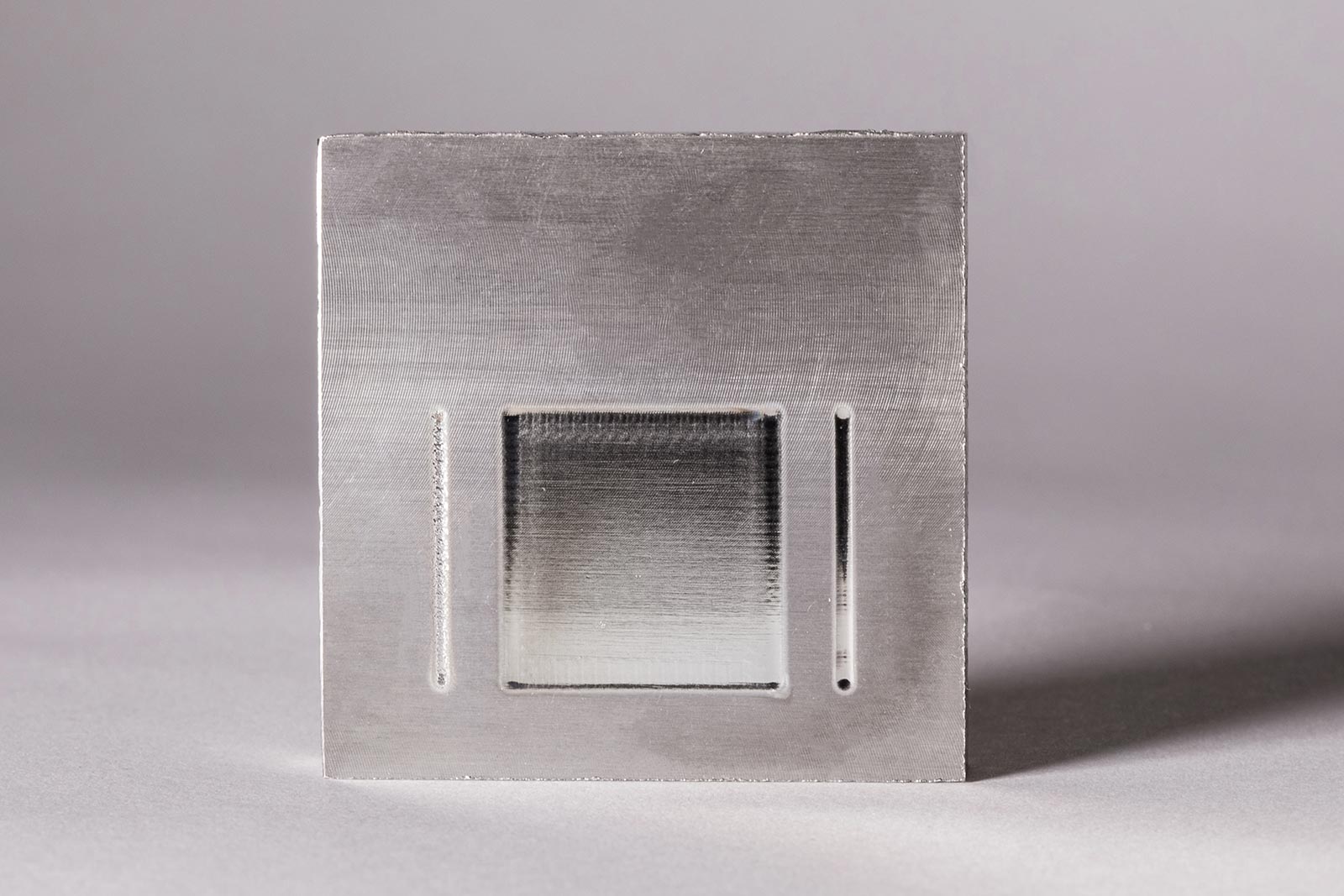

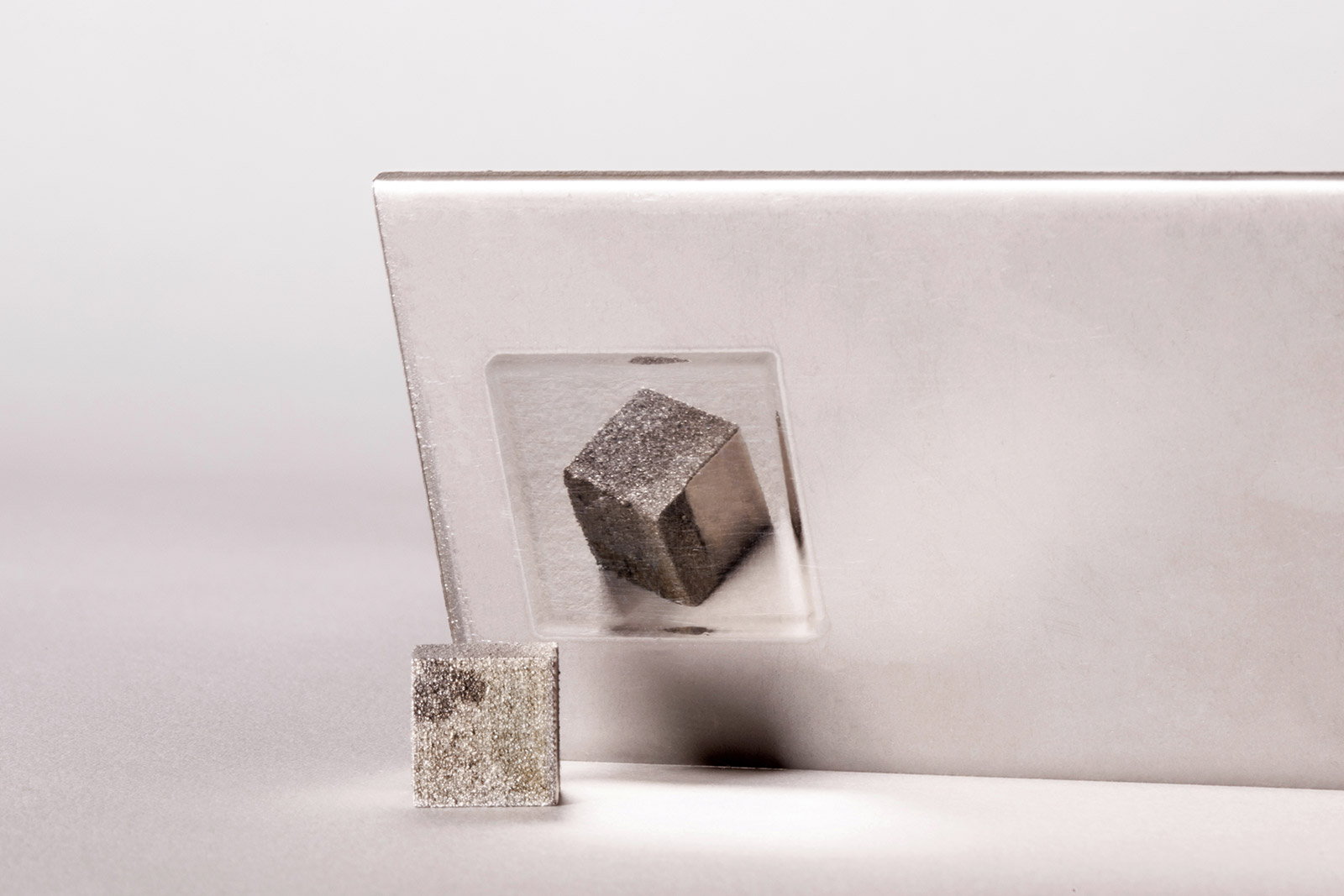

Machining

Definion provides the ability to machine ultra hard materials such as hastelloy, inconnel and cobalt chrome without the cost of buying and maintaining expensive tools.

Traditional CNC machining of ultra hard materials can result

in the work piece cracking at any point in the machining process. If this occurs at the end of a long cycle, considerable cost and waste is incurred.

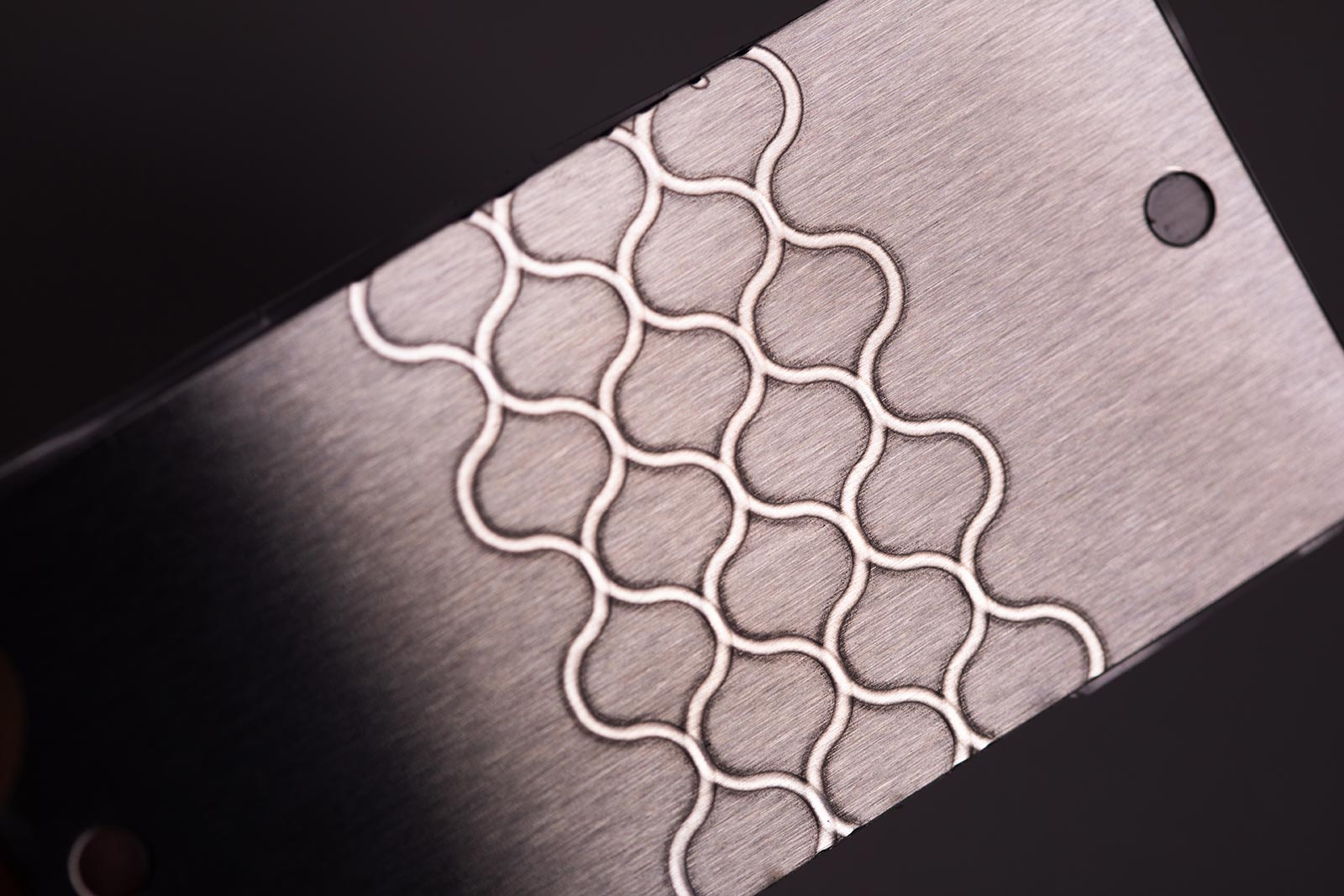

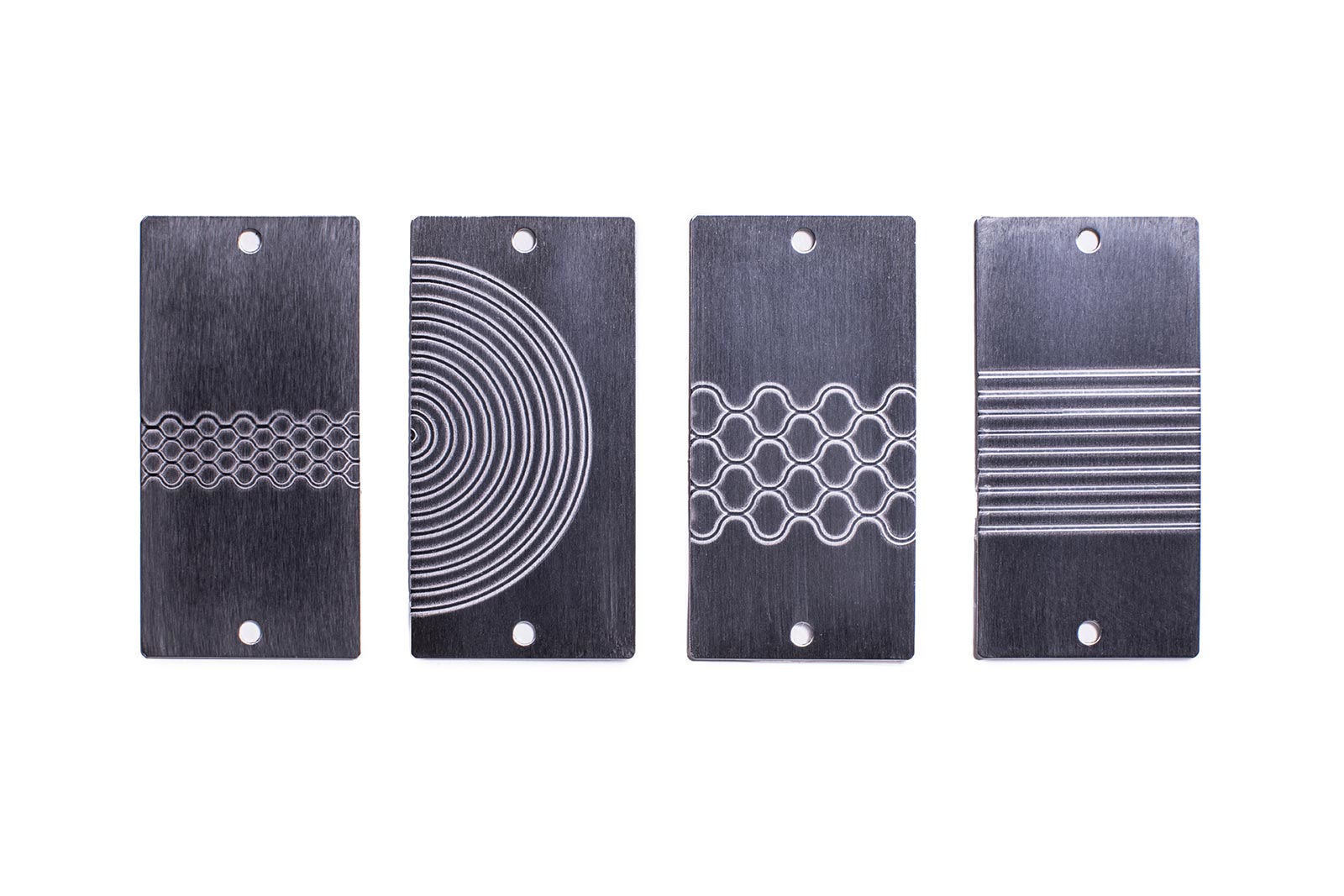

Structuring

Definion provides the ability to add micro features to produce functional surfaces.

Functional surfaces are important to provide features that improve the properties of the material such as adhesion, creating liquid or gas layers or reducing corrosion.

Current methods for structuring can be with high cost femto second lasers or aggressive chemical treatments. Neither of which can be easily implemented by non specialists. The Definion process allows a heat free sterile, non contact process out of the box.

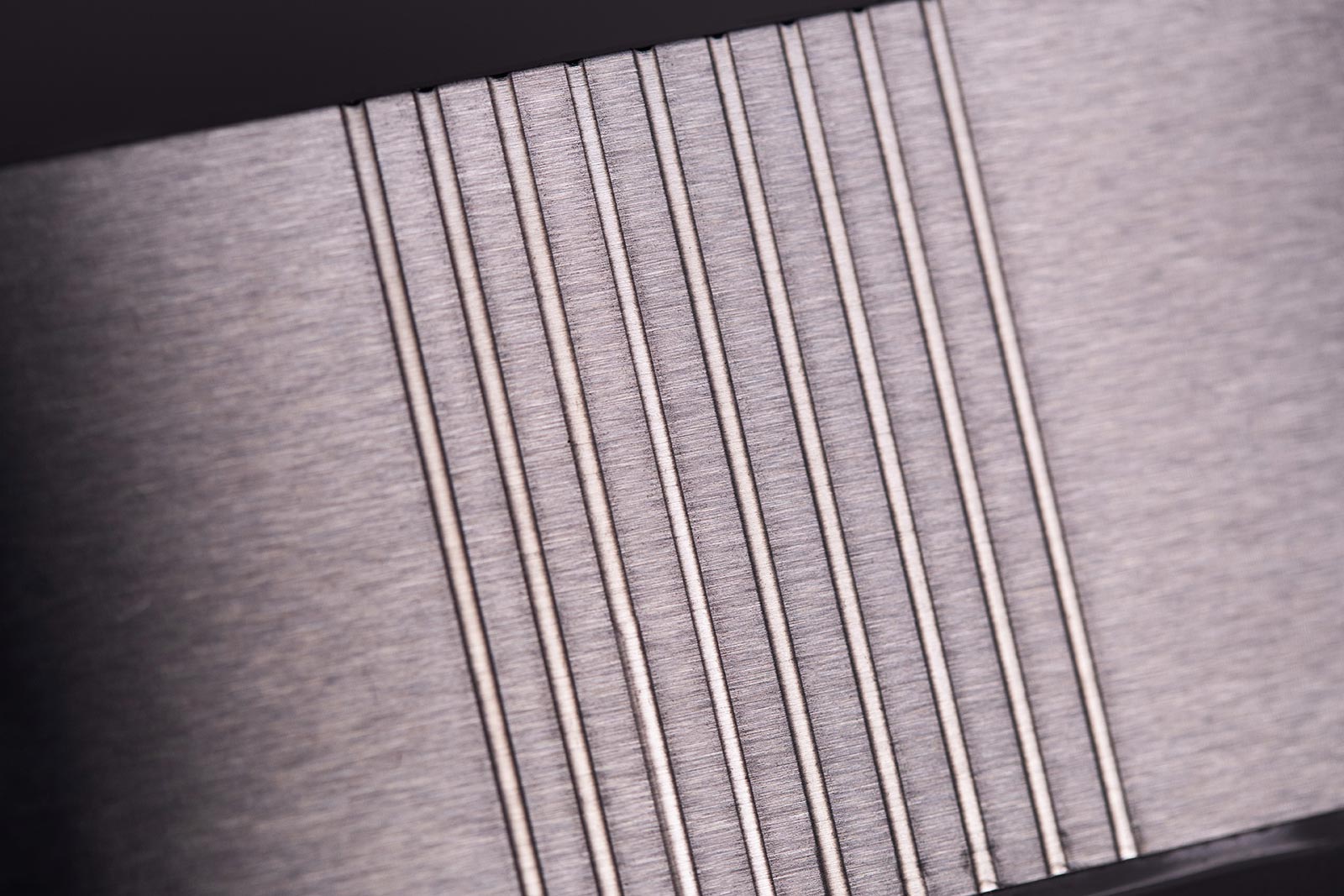

Hole Drilling

Hole drilling using traditional methods, particularly in thin and hard materials, can damage the material and leave burrs within the hole.

Definion can provide holes without sub surface stress or micro cracking, including blind holes without an exit channel.

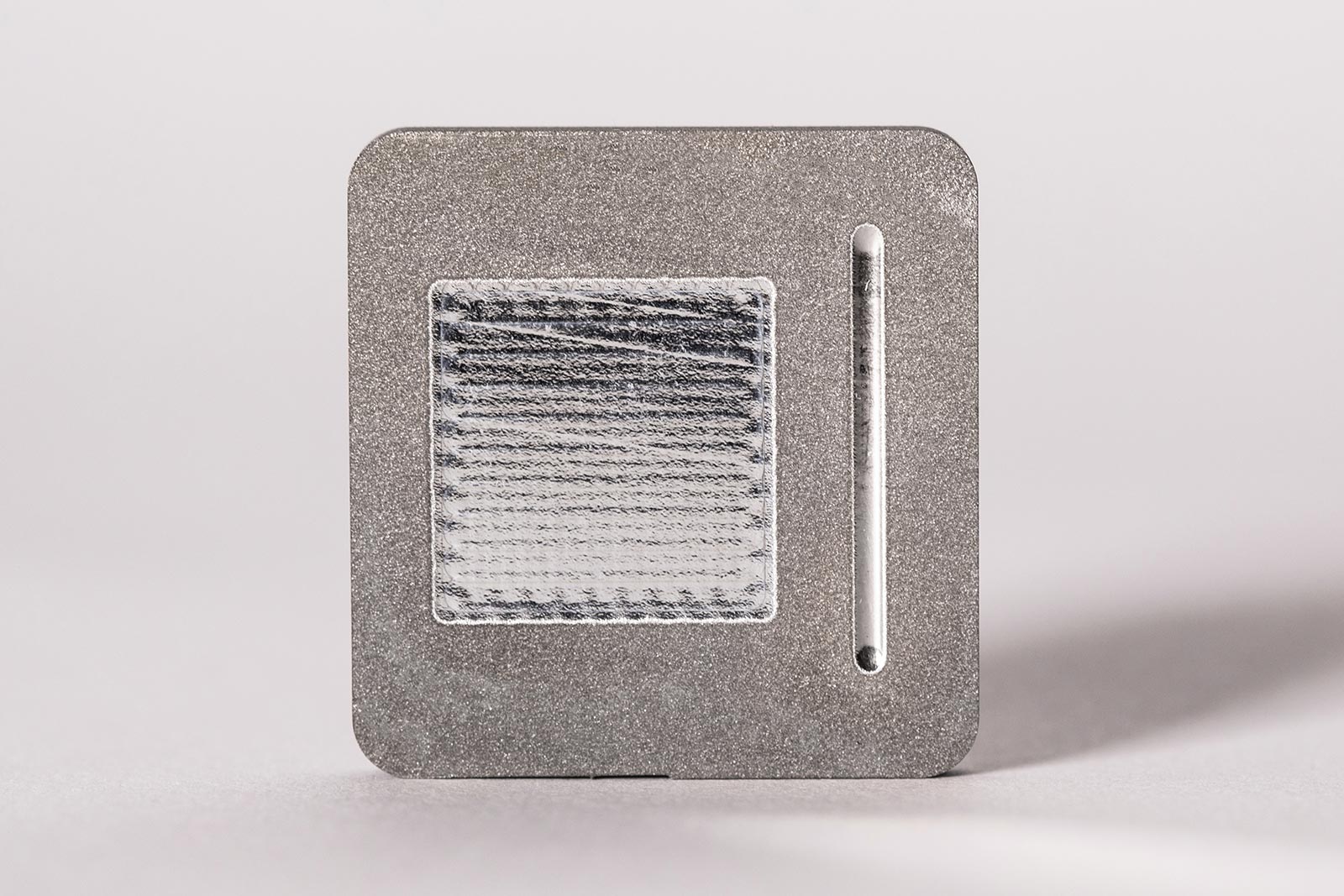

Grain Reveal

Revealing the grain structure of metals and alloys.

Definion provides a non destructive technique for revealing the underlying grain structure in metals and alloys. The process replaces multiple laborious mechanical and polishing steps which can take hours, with a single step process, revealing the grain structure of metals and alloys within a matter of seconds.